Our Services

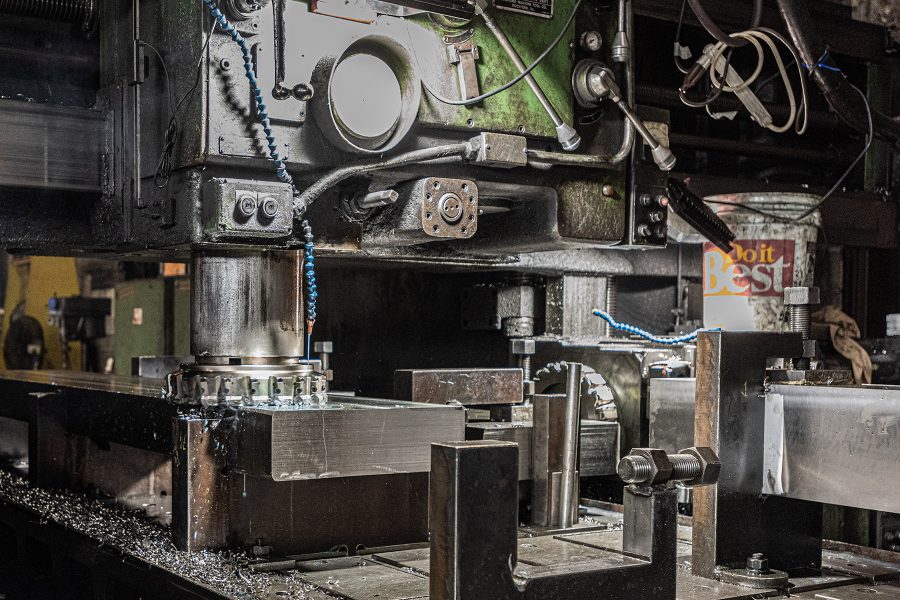

Milling

Milling is a common form of machining used to cut excess material from a metal workpiece.

Our five milling machines offer a maximum capacity of 60” wide x 288” long and a table capacity of up to 50,000 lbs.

Milling Machines

Rockford Double Housing Planer Mill with a table size of 60" x 60" x 168"

- 60” wide between the two columns

- 48” x 193” Table Size

- 60” height under rail

- Tolerance +/-.015″

ROCKFORD DOUBLE HOUSING PLANER MILL WITH A TABLE SIZE OF 72" X 60" X 289"

- 3 milling heads motors are 50 HP each

- 72” wide x 289” long Table Size

- 60” height from table to cutter head

- Tolerance +/-.030″

- Capacity of 40,000 lbs.

Rockford Double Housing Planer Mill with a table size of 60" x 60" x 168"

- It is equipped with a 50HP motor

- Can mill most grades of material from .50″thk to 60″ wide x 60″ high x 168″ long blocks

- Holds a tolerance of +/-.030

- Capacity of 22,700 lbs.

Farrel Newton Planer Mill with a table size of 60" x 60" x 216"

- It is equipped with a vertical spindle motor 75hp and horizontal spindle motor 75hp

Rockford Double Housing Planer Mill with a table size of 60" x 60" x 289"

- 3 milling heads motors are 50 HP each

- Table size is 60″ wide x 289″ long

- 60″ height from table cutter head

- Tolerance +/-.030″

- 40,000 lbs capacity

Our Quality Management Program is aimed at providing the highest quality level of steel fabricating found in today's market.

Sawing and Shearing Service’s commitment to customer satisfaction and quality includes the implementation of a Quality Management Program. Sawing and Shearing’s overriding objective is to fulfill or exceed our customer’s expectations. Achieving our customer’s satisfaction with every job is Sawing and Shearing’s top priority. Our Quality Management Program is aimed at providing just this; the highest quality level of steel fabricating found in today’s market.

What our clients are saying…

QUALITY CONTROL

Employee Quality

After completing extensive facility and safety training, Sawing and Shearing’s employees support quality assurance through every step of the fabrication process.

Detailed Inspection

Our employees complete detailed inspections throughout the fabrication process, ensuring accuracy and eliminating room for error.

Business Experience

It is our years of experience as a trusted outside steel fabricator that can assure you the job will be done right by Sawing and Shearing Services.

We are dedicated to providing high-quality services to each of our clients, and the assurance their project is constructed to meet their highest expectations.

Open communication and a clear understanding of required quality standards between us and our client is essential. The quality process should focus on prevention of errors and elimination of rework as well as on testing and inspection. And finally, client satisfaction is vital to both of our continued success.