Our Services

Tube Laser

Fiber laser technology

- High-speed cutting in a class of its own, 4 kilowatts of laser power.

- Outstanding cutting performance for high parts output and excellent cutting quality with thin to medium wall thickness

- Wide range of applications. In addition to steel, stainless steel, and aluminum, non-ferrous metals can also be processed with excellent quality

Tube Laser Cutting Machine

BYTUBE STAR 130 FIBER TUBE LASER WITH 28' ENTRANCE TABLE AND 13' EXIT TABLE. 4kw POWERSOURCE.

- .375″OD min to 5″OD or 5″Sq max

- Steel (max. cutting thickness) .59”

- Stainless steel (max. cutting thickness) .312”

- Aluminum (max. cutting thickness) .312”

- Brass (max. cutting thickness) .25”

- Copper (max. cutting thickness) .25”

DIMENSIONS

- Round tubes (min-max): .375”-5”

- Square tubes (min-max): .375”sq – 5”sq

- Rectangular tubes (min-max): .375” -5.1”

- Other tubes (min-max. length of sides): .375”-5”

Technical specifications for the ByTube Star 130

| ByTube Star 130 | |

| Min. Tube length (with automatic loading) | 8.2 ft |

| Max. Tube length | 21 – 28 ft |

| Max. Tube weight | 11 lb/ft |

| Tube sections | O ◻ ▯ ⬭ U C L — |

| Dimensions round sections (min. – max.) | Ø 0.375 – 5.1 in |

| Dimensions rectangular sections (min. – max.) | 0.375 x 0.375 – 5.1 x 5.1 in |

| Dimensions other closed sections (min-max length of the sides) | 0.375 x 0.375 – 5.1 x 5.1 in |

| Dimension flat bars | 1.5 – 5 in |

| Thickness flat bars | 0.2 – 0.59 in* |

| Max. linear speed of axis X / Y / Z | 656.16 / 196.8 / 196.8 ft/min |

| Max. rotation speed of mandrels | 250 r.p.m. |

| Max. piece length unloading system | 6.56 – 13.12 – 20 ft |

| X, Y and Z axis positioning precision** | ± 0,003 in |

| Number of controlled axis | 8 |

| Machine weight*** | 22 046.2 lbs |

| Numeric Control | BySoft Cell Control Tube |

* According to laser power

** According to ISO 230-2:2014(E)

*** Entire plant without extraction, cooling unit and bowl feeder

Our Quality Management Program is aimed at providing the highest quality level of steel fabricating found in today's market.

Sawing and Shearing Service’s commitment to customer satisfaction and quality includes the implementation of a Quality Management Program. Sawing and Shearing’s overriding objective is to fulfill or exceed our customer’s expectations. Achieving our customer’s satisfaction with every job is Sawing and Shearing’s top priority. Our Quality Management Program is aimed at providing just this; the highest quality level of steel fabricating found in today’s market.

What our clients are saying…

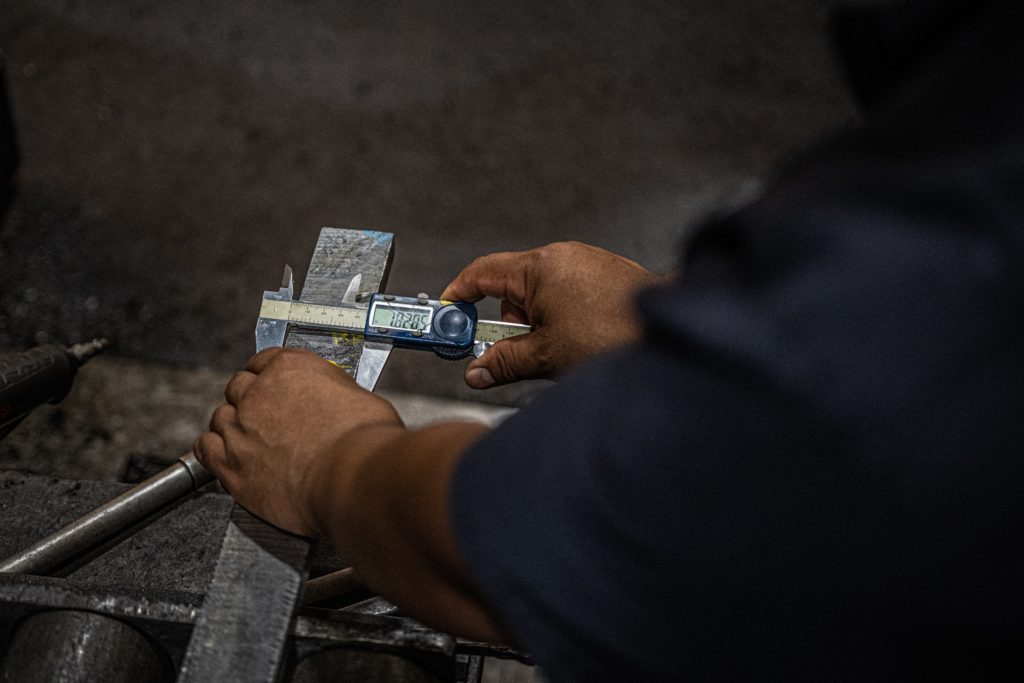

QUALITY CONTROL

Employee Quality

After completing extensive facility and safety training, Sawing and Shearing’s employees support quality assurance through every step of the fabrication process.

Detailed Inspection

Our employees complete detailed inspections throughout the fabrication process, ensuring accuracy and eliminating room for error.

Business Experience

It is our years of experience as a trusted outside steel fabricator that can assure you the job will be done right by Sawing and Shearing Services.

We are dedicated to providing high-quality services to each of our clients, and the assurance their project is constructed to meet their highest expectations.

Open communication and a clear understanding of required quality standards between us and our client is essential. The quality process should focus on prevention of errors and elimination of rework as well as on testing and inspection. And finally, client satisfaction is vital to both of our continued success.