Our Services

Press Break

High Performance Hydraulics

- Hydraulic System: High-performance hydraulic actuation ensures smooth, consistent operation and energy efficiency.

- Tooling Compatibility: Supports a range of tooling options, including precision-ground punches and dies, for flexible manufacturing.

- Accuracy: ±0.0005” ram positioning for high-precision bending applications.

Press Break Machine

Cincinnati 230CB x 12’ Press Brake

- Capacity: 230 Tons

- Overall Length or Bed and Ram: 12′

- Distance Between Housings: 10′ 6 3/4″

- Stroke: 10″

- Open Height: 17″

- Closed Height: 7″

- Throat Clearance: 8″

- Speeds:

- Approach: 101 IPM

- Form: 14-49 IPM

- Return: 95 IPM

- Motor: 25 HP

Our Quality Management Program is aimed at providing the highest quality level of steel fabricating found in today's market.

Sawing and Shearing Service’s commitment to customer satisfaction and quality includes the implementation of a Quality Management Program. Sawing and Shearing’s overriding objective is to fulfill or exceed our customer’s expectations. Achieving our customer’s satisfaction with every job is Sawing and Shearing’s top priority. Our Quality Management Program is aimed at providing just this; the highest quality level of steel fabricating found in today’s market.

What our clients are saying…

QUALITY CONTROL

Employee Quality

After completing extensive facility and safety training, Sawing and Shearing’s employees support quality assurance through every step of the fabrication process.

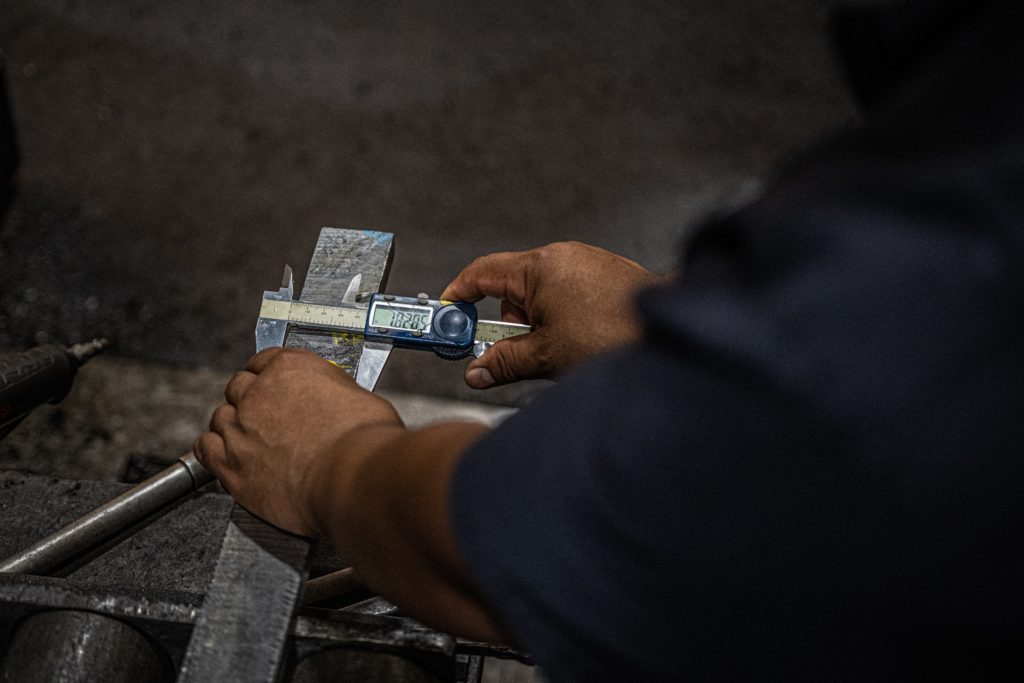

Detailed Inspection

Our employees complete detailed inspections throughout the fabrication process, ensuring accuracy and eliminating room for error.

Business Experience

It is our years of experience as a trusted outside steel fabricator that can assure you the job will be done right by Sawing and Shearing Services.

We are dedicated to providing high-quality services to each of our clients, and the assurance their project is constructed to meet their highest expectations.

Open communication and a clear understanding of required quality standards between us and our client is essential. The quality process should focus on prevention of errors and elimination of rework as well as on testing and inspection. And finally, client satisfaction is vital to both of our continued success.